Subtotal: $2,430.88

10.4″ Industrial computer monitor 10 Inch Capacitive Touch Screen 1024*768 With VGA/DVI/HDMI/USB Interface Mini PC screen

$380.60 – $391.00

10.4 inch industrial monitor capacitive touch

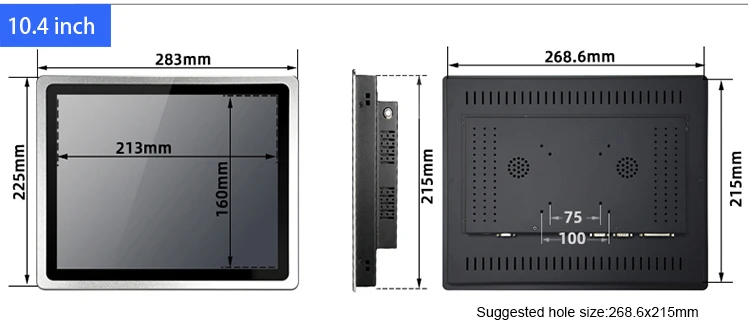

Datasheet for our 3mm bezel aluminum 10.4 inch thin flat lcd PC monitor:

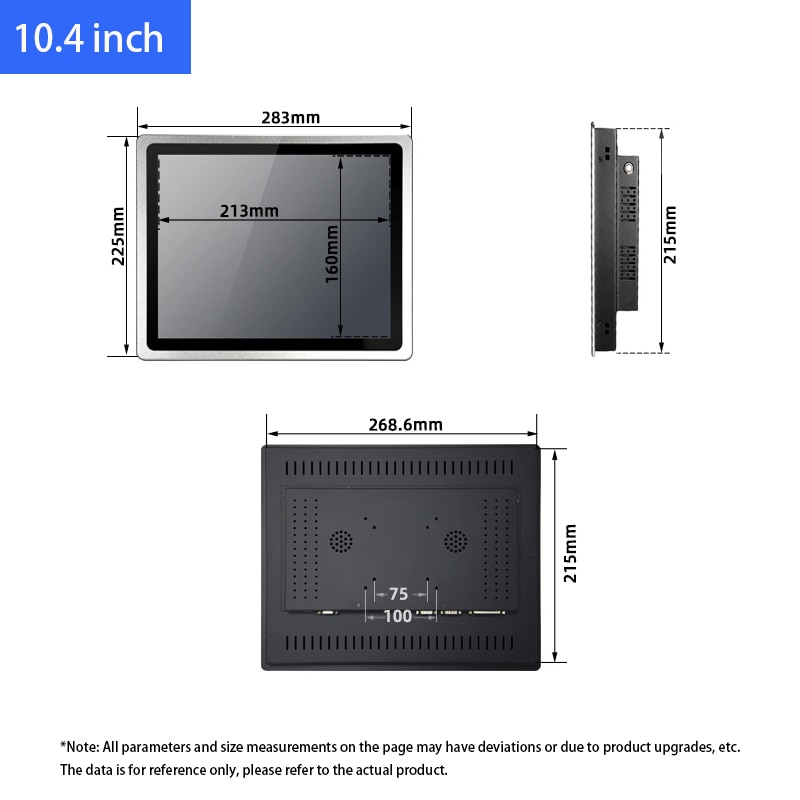

Size:10.4 inch Panel Type:Industrial Touch Screen LCD Monitor Resolution:1024*768 Aspect Ratio:4:3 Active Area (mm):213*160mm Interface:Optional VGA,DVI+VGA,HDMI+VGA Luminance|:250nit-400nit(The default is 300cd/m2 ) Response time:5ms Display colors:16.7M(8-bit) View angle:80/80/80/80 Touch screen parameters Touch technology: capacitive technology (ten points) Effective touch recognition: >1.5mm Communication method: Full-speed USB 2.0, 3.0 Theoretical clicks: more than 50 million times Touch principle: current sensing Surface hardness: Physically toughened, Mohs grade 7 explosion-proof glass Operating system compatibility: Windows7/Windows8/CE/Mac/Android/Linux/XP Drive: free drive, plug and play

Other parameters

Input power: 100-220V AC 50/60H Output power: 12V 3-5A Whole machine power consumption: <26W Standby power consumption: <3w Working temperature: -20℃-70℃ Working humidity: 0%-90% (no cold doubt) Storage temperature: -40℃-85℃ Storage humidity: 10%-95% (no cold doubt)

Optional interface:

1.VGA+Touch USB 2.VGA+DVI+Touch USB 3.VGA+HDMI +Touch USB

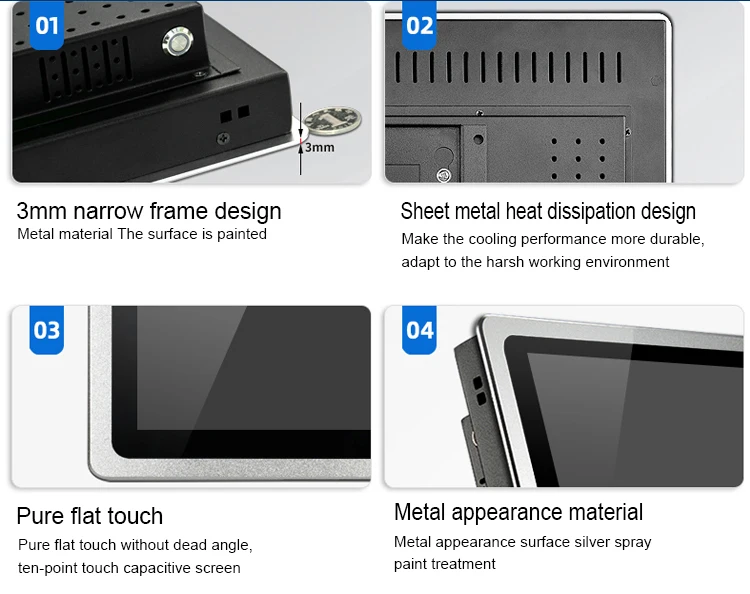

The flat front panel is dustproof and waterproof

Aluminum alloy front frame is durable, dustproof and waterproof

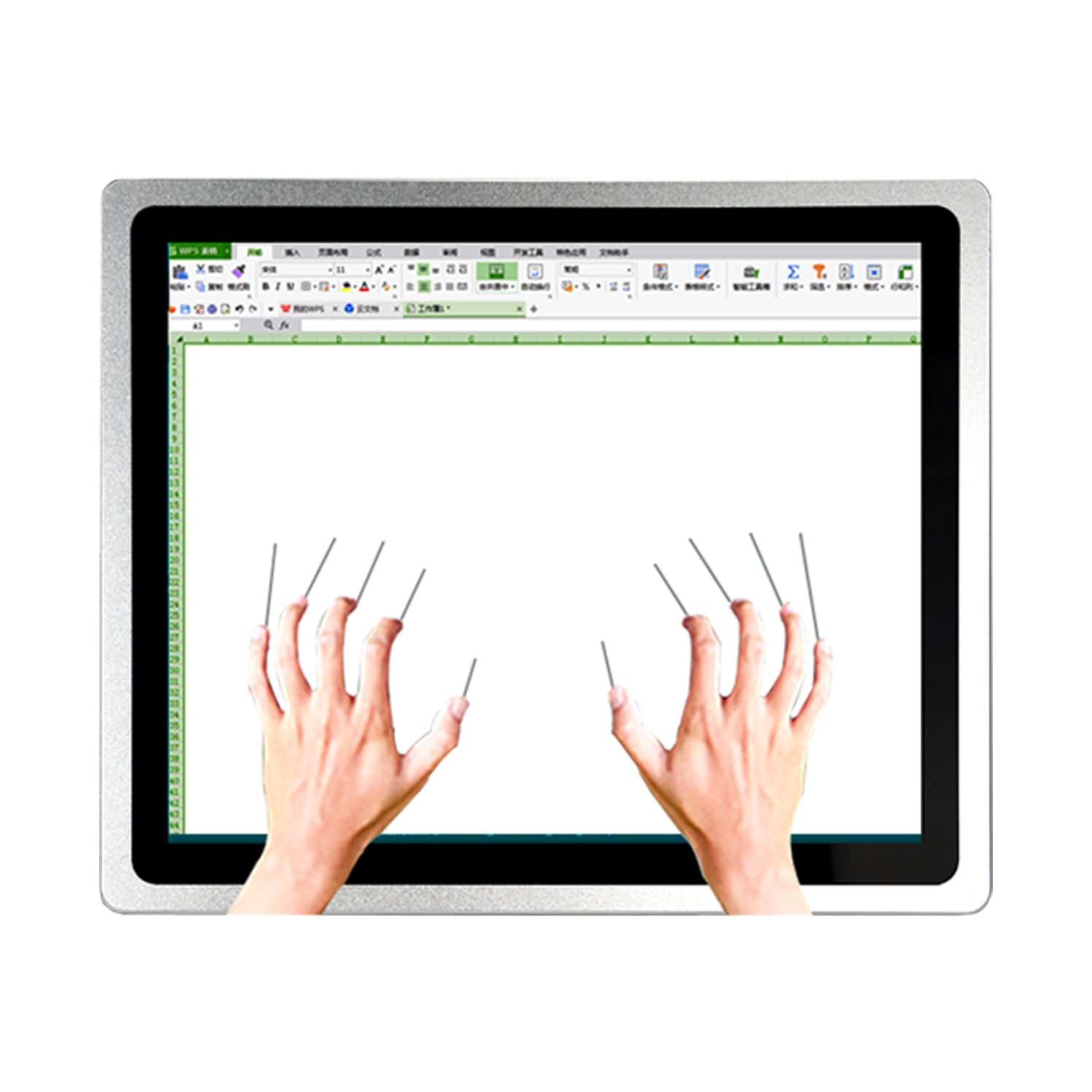

Capacitive touch (ten-point touch)

Support a variety of gesture touch, sensitive response, stable touch. Sensitive touch makes it easier to use. The sensing accuracy is higher, the response speed is faster, and the surface has a smooth or matte surface treatment. Support more refined industrial operation touch, no blind spots.

10.4 inch monitor size

Capable of working 24 hours a day

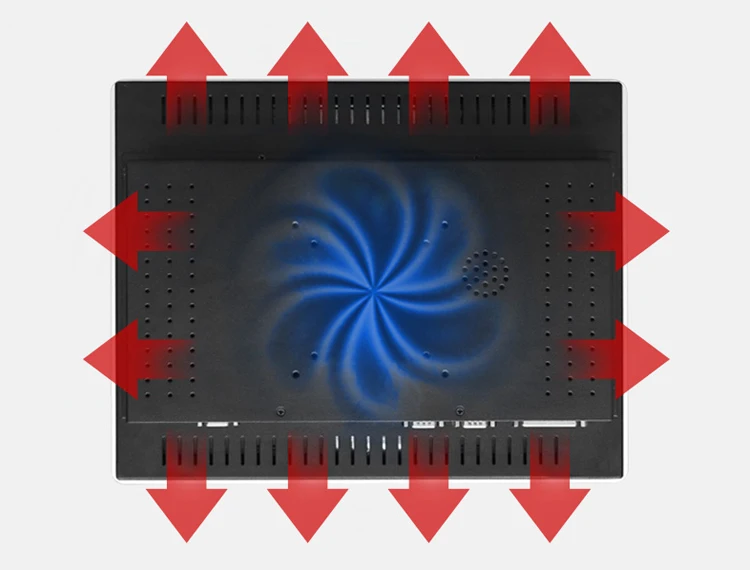

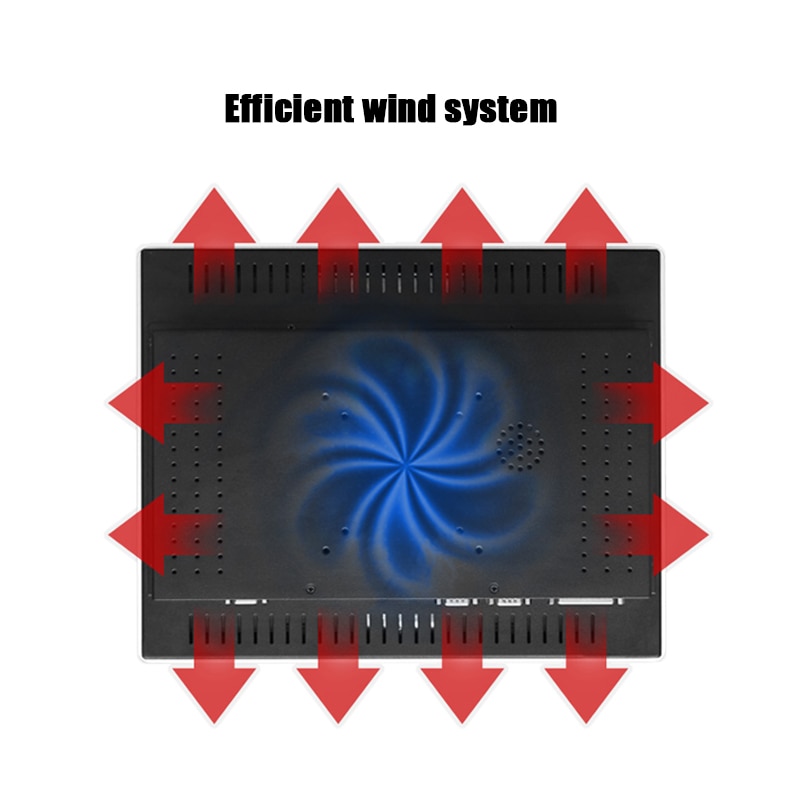

Industrial-grade heat dissipation design

Industrial-grade heat dissipation design with high standard technology, metal cold-rolled plate body design, multi-row heat dissipation hole design, bring better industrial use experience, fast heat dissipation, and quiet

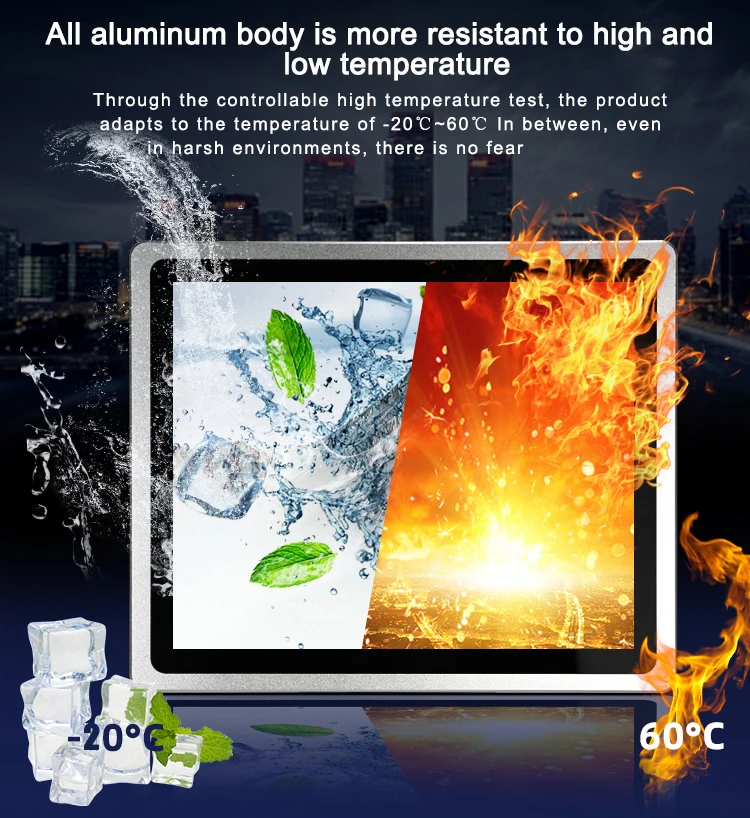

Aluminum body is more resistant to high and low temperatures

Oxidized brushed aluminum alloy front panel, steel body is forged by cold rolling process, Greatly increase the rigidity and compression resistance of the fuselage. After strict temperature control box test, it runs stably in harsh environment with large temperature difference, standard industrial temperature difference is -20℃ to 60℃

Features

Aluminum alloy pure plane board, seamless design, the frame is made of high-quality aluminum alloy, The back panel adopts the sheet metal baking varnish process, the whole machine looks suitable and elegant, and the quality is reliable, sturdy and durable

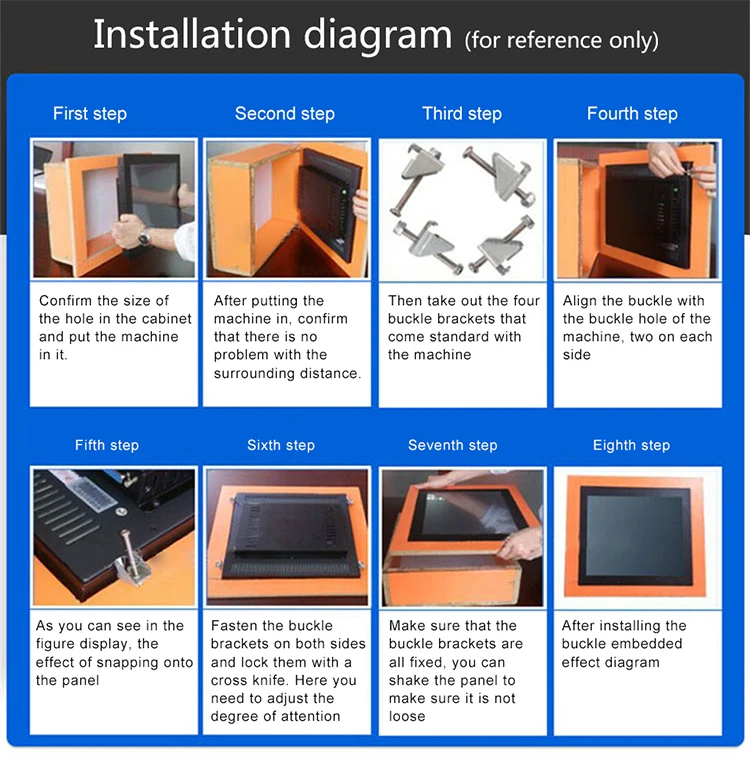

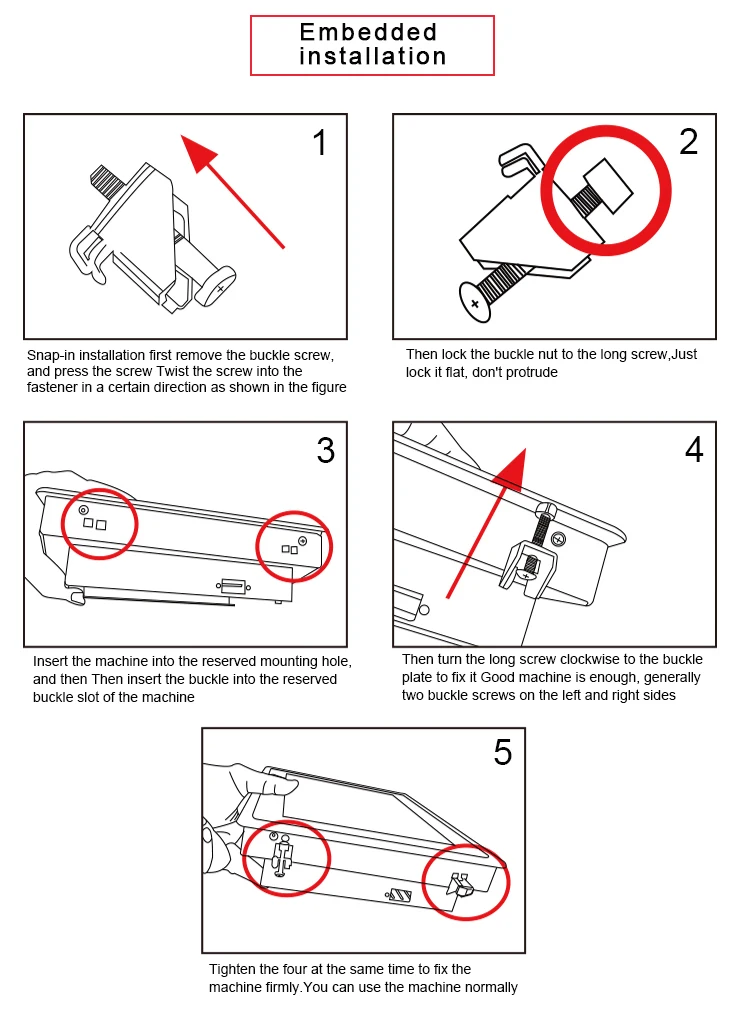

Installation method

1. Embedded installation ①The cabinet needs to be opened before installation, and the opening size should be slightly larger than the opening size specified by the product. ②Place the product in the embedded installation opening reserved on the installation panel. ③There are two square holes on both sides of the equipment. When installing, use one end of the buckle to buckle the square hole, and the screw head on the buckle to hold the cabinet. Then tighten the screws, the installation method of the other three prescription holes is the same, and the embedded installation can be completed.

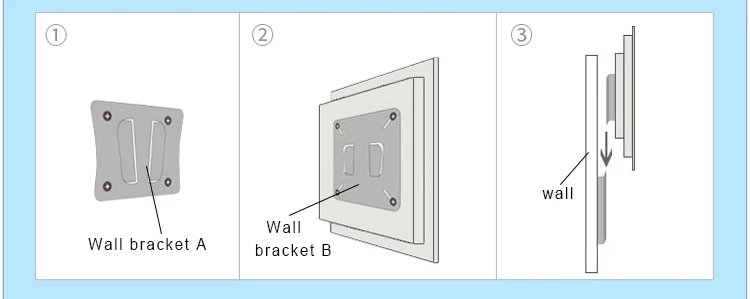

2. Wall-mounted installation

① Fix the wall bracket A on the wall with expansion screws. ②The wall bracket B is installed on the back of the all-in-one with screws. ③The back bracket of the all-in-one is inserted into the wall bracket to complete the installation.

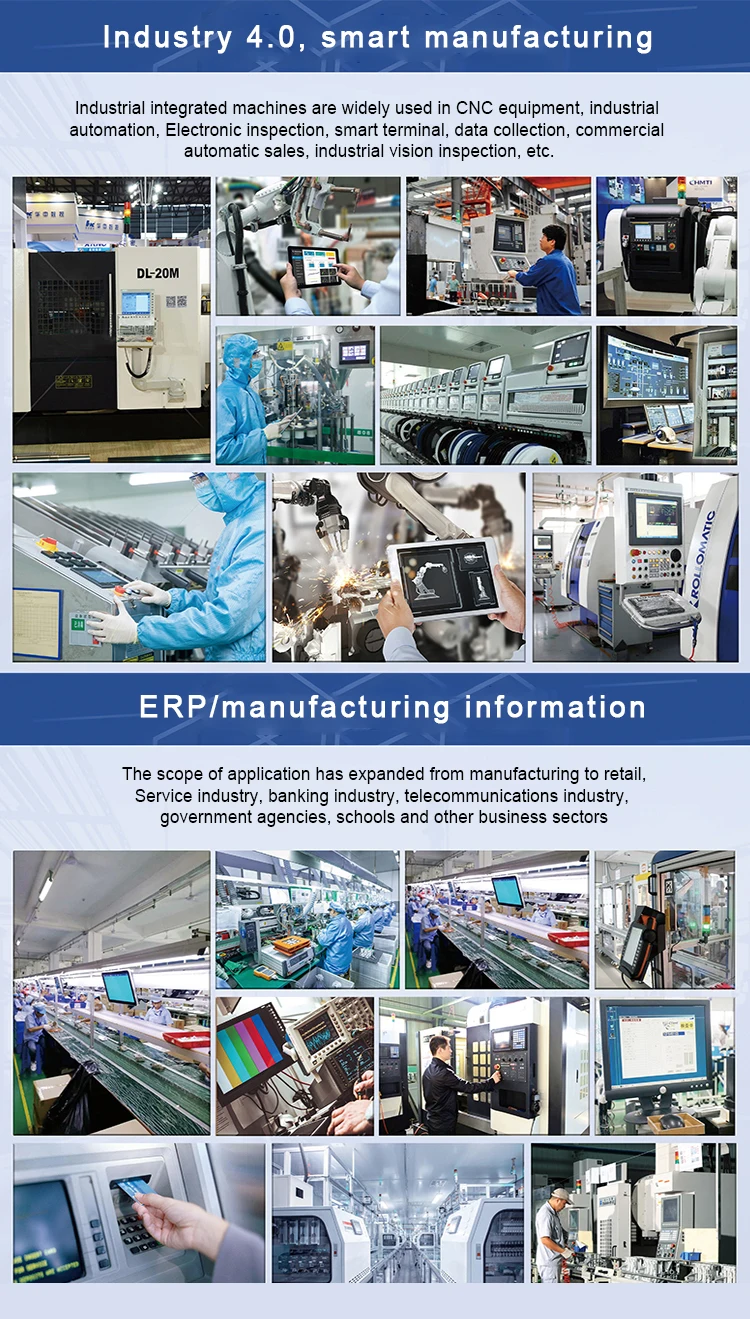

Wide range of applications

Applied to Smart City/Smart Education/ Smart transportation/smart parts/smart medical/industry 4.0 We can research and develop scenarios that require an all-in-one machine

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

Intel Xeon X3440 CPU Xeon Processor X3440 (8M Cache, 2.53 GHz)) LGA1156 Desktop CPU

Intel Xeon X3440 CPU Xeon Processor X3440 (8M Cache, 2.53 GHz)) LGA1156 Desktop CPU  Laptop computer Screener CX70 2QF-621XPL 17.3" 4210

Laptop computer Screener CX70 2QF-621XPL 17.3" 4210

There are no reviews yet.