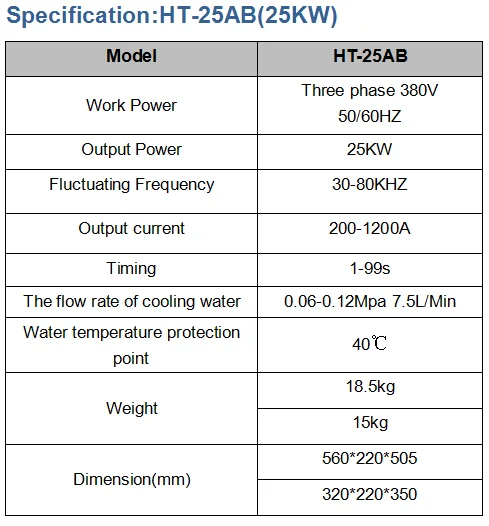

3 phase 380V 25KW IGBT type Induction heating machine for billets forging

€2,218.72 €2,335.50

PRODUCT INFORMATION

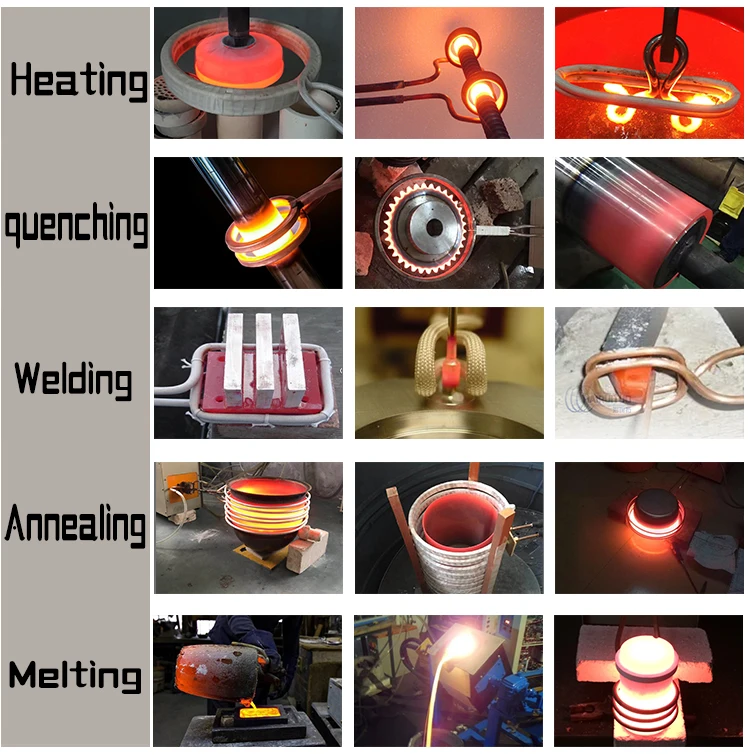

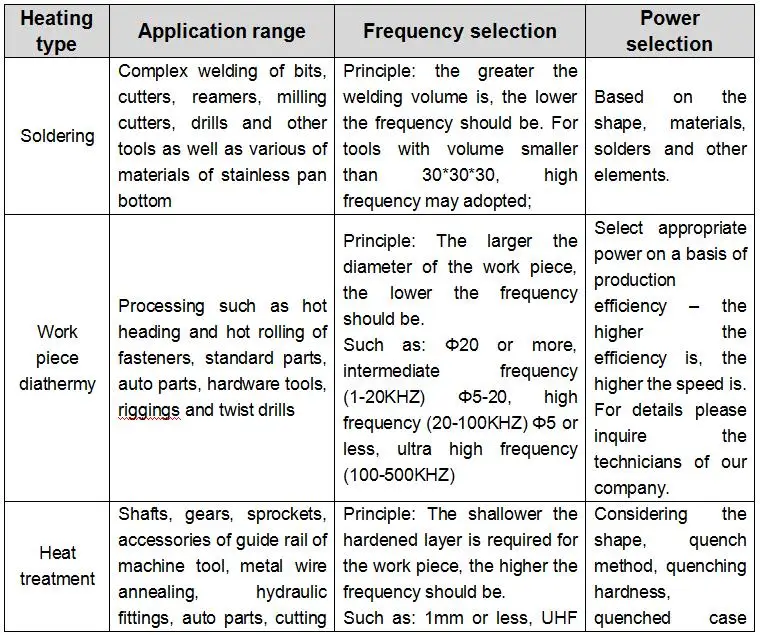

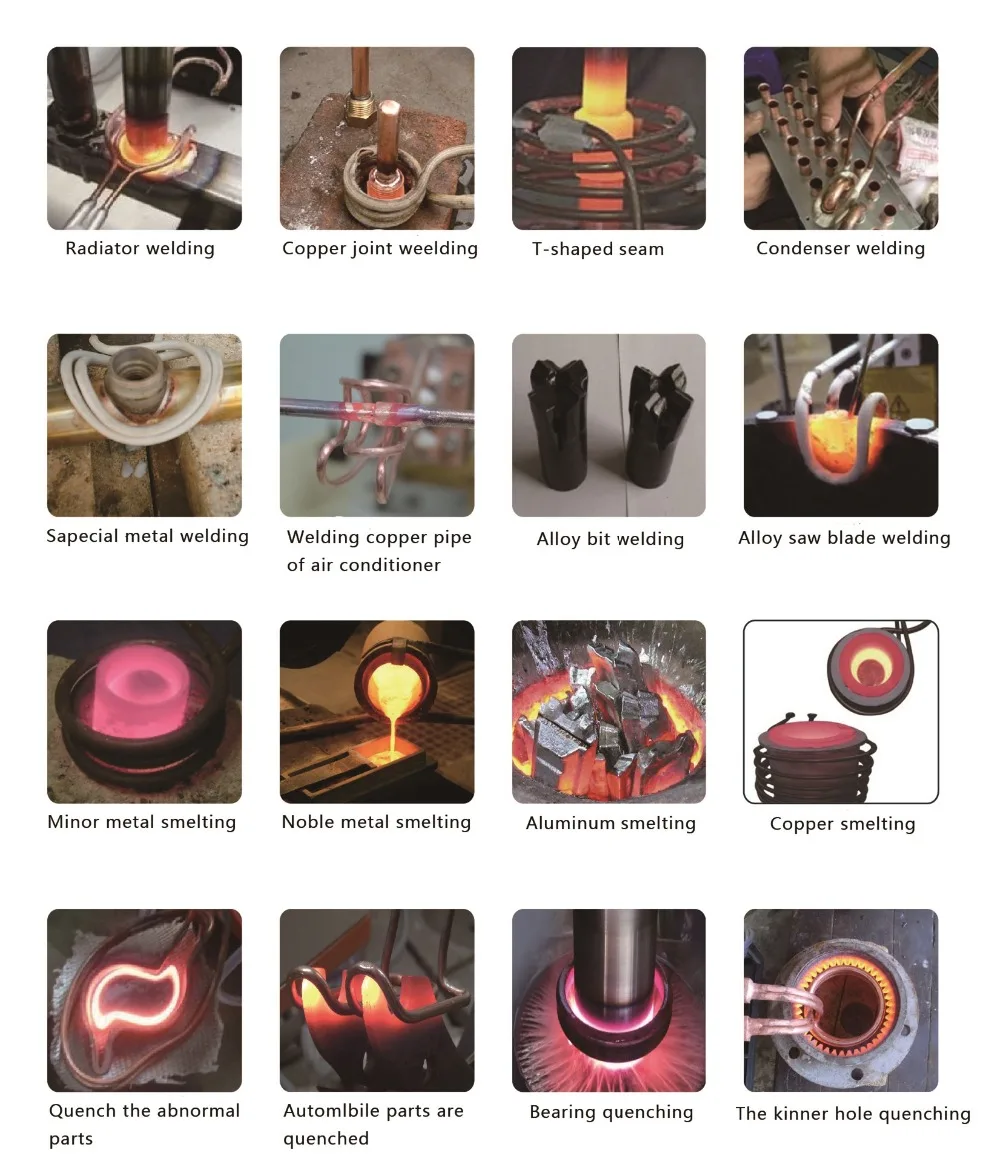

Application of Induction heating equipment:

-

Hot forging aims to fabricate the work pieces of certain temperature (different materials require different temperatures) into other shapes through forging press with the help of punch press, forging machine or other equipments for instances, hot extrusion of watch case, watch flan, handle, mold accessory, kitchen and table ware, art ware, standard part, fastener, fabricated mechanical part, bronze lock, rivet, steel pin and pin.

-

Hot fitting refers to the connection of different metals or metals with nonmetals through the heating based on the principle of hot expansion or hot smelting, for instances, embedded welding of copper core of computer radiator with aluminum sheet and speaker web, compound of steel and plastic tube, sealing of aluminum foil (tooth paste peel) motor rotor and sealing of tubular electric heating element.

-

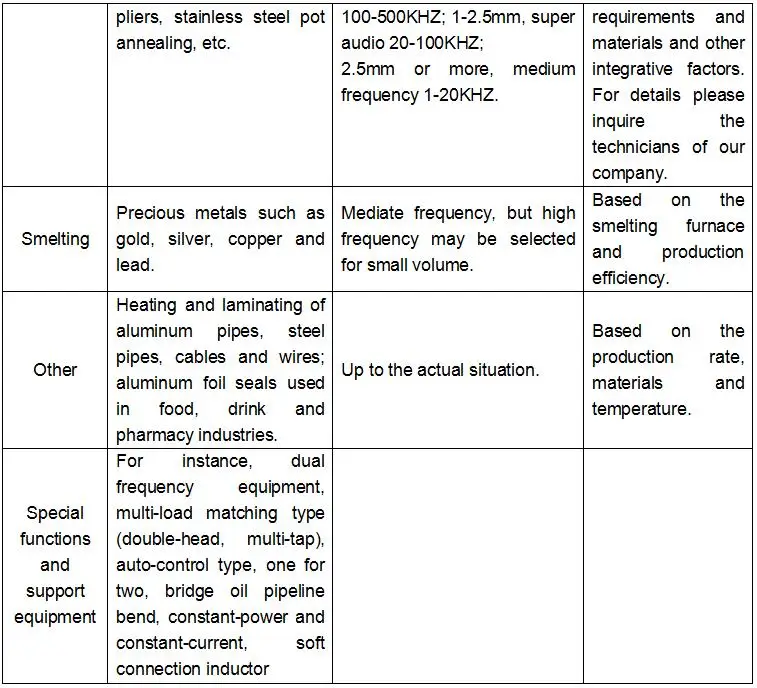

melting mainly aims to melt the metal into liquid by using the high temperature, which is applicable to the smelting of iron, steel, copper, aluminum, zinc as well as various noble metals.

Heat treatment (surface quenching):

-

Quench for various hardware and tools, such as pliers, wrench, hammer, ax, screwing tools and shear (orchard shear).

-

Quench for various automobile and motorcycle fittings, such as crankshaft, connection rod, pinton pin, chain wheel, aluminum wheel, valve, rock arm shaft, small shaft and fork. Various electric tools, such as axes and gear.

-

Quench for machine tools, such as lache deck and guide rail.

-

Quench for various hardware metal parts and machined parts, such as shaft gear (chain wheel) cam, chuck and clamp. Etc.

-

Quench for hardware molds, such as small size mold, mold accessory and inner hole of mold

Welding (brazes welding, silver soldering and brazing):

-

Welding of various hardware cutting tools, such as diamond tool, abrasive tool, drilling tool, alloy saw blade, hard alloy cutter, milling cutter, reamer, planning tool and solid center bit.

-

Welding of various hardware mechanical gadgets, silver soldering and brazing of metals of the same varieties, such as hardware toilet and kitchen products refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

-

Compound pot bottom welding is mainly applicable to the braze welding circular, square as well as other irregular plain pot bottom. It is also applicable to plain braze welding of other metals.

-

Welding of heating disc of electric hot-water kettle mainly refers to the braze welding stainless steel flat base, aluminum sheet and tubular electric heating elements of various forms.

Annealing (tempering and modulation):

-

Annealing of various stainless steel products, such as stainless steel basin, annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

-

Annealing of various other metal work pieces, such as golf ball head, cue, brass lock, hardware copper fitting, kitchen knife handle, blade, aluminum pan, aluminum pail, aluminum radiator and various aluminum products.

Main Parts Introduction:

|

Adopts the latest MOSFET, IGBT power units and frequency conversion control techniques with high efficiency, low energy consumption and high output power. |

| The integrated filter capacitor is used after the technology upgrade, the performance is more stable, the power output is larger, and the fault caused by the manual plug-in is effectively reduced. |

|

|

The motherboard is independently developed by our engineering department to ensure that all components are genuine and will be tested after assembly. |

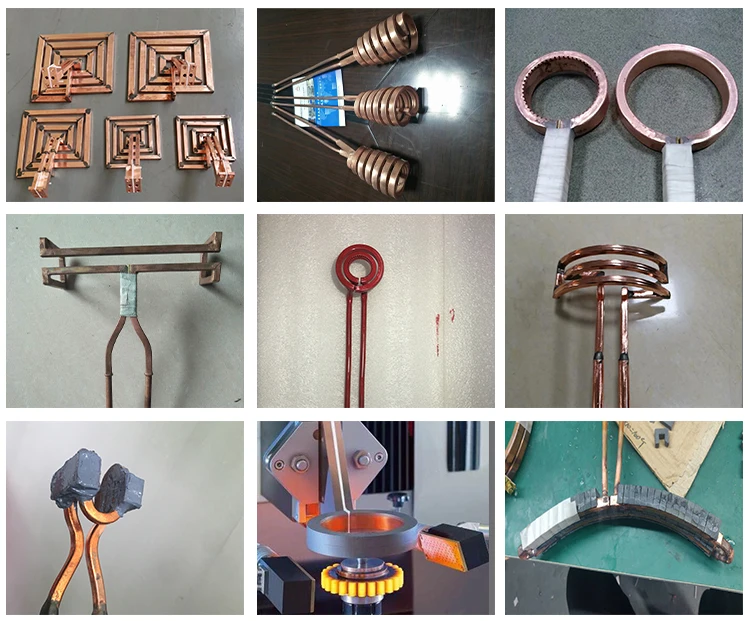

THE APPLICATION DIAGRAM OF EQUIPMENT

The coil can be customized, welcome contact us if you have any requirements.

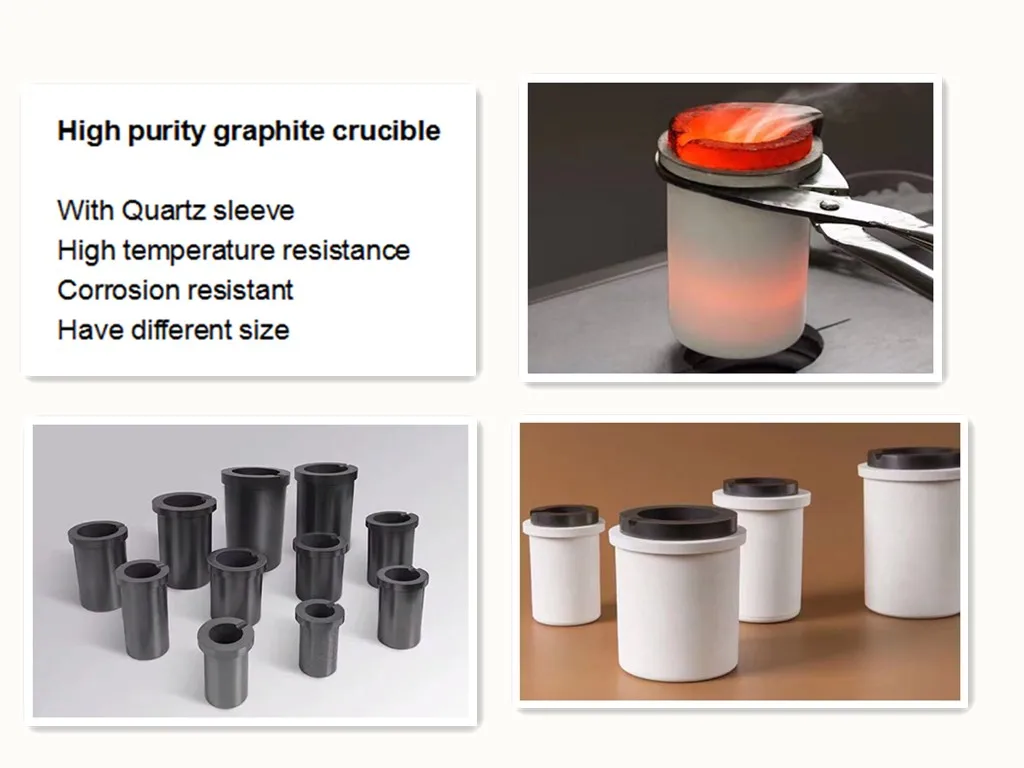

The graphite crucible have different size, welcome contact us if you need it (Need extra charge)

FAQ

Are you are a manufacturer or trad company?

We are manufacturer. Our factory produce and export all kinds of induction heating machine. We also can design and develop the induction heating machine according to your requirements.

Warmly welcome to visit our factory and contact us.

May I have a sample test before I place an order?

Yes, sample test will be available if necessary.

How about your standard delivery date?

If have storage will be 1day.if have to produce 7-10 days. Our company provide just-in-time delivery.

If the machine get damaged, what can i do?

If the fault caused by non-artificial reason, In the guarantee time (1 year) , we will send the spare parts to you for free. And provide the technical consultant for anytime.

How about your factory service?

Pre-sale service:

1: We will recommend the most suitable machine for you and

2: We can offer sample testing support.

In-sale service:

1: We will produce the machine according to relevant technical standards.

2: Strictly check up the machine before delivery

3: Delivery on time.

After-sale service:

If you have any questions after receiving the goods, please feel free to contact us. We will give the best solution

Why choose you?

More than 10 years experience in induction heating field. Our heating equipment export to America , Russia, Southeast Asia, Africa and Europe etc. Fast, timely delivery & reliable after sales service Customers & Quality first.

Adopts the latest MOSFET , IGBT power units and frequency conversion control techniques with high efficiency, low energy consumption and high output power. (Use Germany SIMENS INFINEON ON IGBT)

FACTORY INFORMATION

The warranty year of this product is one year ( non-human damage)

window.adminAccountId=233224060;

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.